Can Raspberry Pi Replace PLCs? A New Era of Industrial Control

|

|

Tiempo de lectura 6 min

|

|

Tiempo de lectura 6 min

Industrial automation has long relied on Programmable Logic Controllers (PLCs) —rugged, reliable, and purpose-built systems designed to operate in harsh environments. But in recent years, Raspberry Pi and other single-board computers (SBCs) have emerged as powerful, flexible, and affordable alternatives, raising the question: Can SBCs replace PLCs in modern industrial applications?

Let’s compare these two technologies and explore how SBCs are reshaping the landscape of industrial electronics.

Want to know more? Visit our store

Table of Content

PLCs:

Designed for real-time, deterministic control

Limited processing power, optimized for specific I/O operations

Programmed using ladder logic, function block diagrams, or structured text

Raspberry Pi / SBCs:

Feature-rich CPUs with multicore processing

Capable of running full operating systems (Linux, Windows IoT)

Support Python, C++, Node-RED, and open-source control frameworks like OpenPLC

✅ Advantage: SBCs offer broader programming flexibility and higher processing power at a fraction of the cost.

While Raspberry Pi and other SBCs offer compelling features, they also come with limitations. Here's a side-by-side comparison of the key pros and cons of each approach:

✅ Cost-Effective : Low entry price, scalable with inexpensive accessories.

✅ Programming Flexibility : Supports modern languages like Python, C++, and Node-RED.

✅ Connectivity : Native support for Ethernet, Wi-Fi, Bluetooth, and USB.

✅ Open Source Ecosystem : No vendor lock-in; access to a global developer community.

✅ IIoT-Ready : Seamless integration with cloud platforms and smart sensors.

✅ Industrial-Grade Durability : Engineered for harsh, high-vibration environments.

✅ Reliable Uptime : Designed for 24/7 operation in mission-critical systems.

✅ Deterministic Control : Optimized for real-time I/O handling.

✅ Long-Term Support : Vendor-backed updates, spares, and lifecycle planning.

⚠️ Not Rugged by Default : Needs added protection for industrial environments.

⚠️ Power Instability : Susceptible to brownouts or power interruptions without UPS.

⚠️ Limited Real-Time Control : Lacks native deterministic timing for time-critical tasks.

⚠️ Shorter Lifecycle : Consumer-grade hardware with limited support cycles.

⚠️ High Cost : Expensive initial investment and expansion modules.

⚠️ Limited Programming : Mostly relies on legacy languages and proprietary environments.

⚠️ Connectivity Gaps : Requires extra modules for cloud or wireless integration.

⚠️ Vendor Lock-In : Often tied to specific ecosystems and licensing structures.

Top Manufactures Products

2. Connectivity and Integration

PLCs:

Offer industrial-grade protocols like Modbus, Profinet, EtherNet/IP

Require additional modules for wireless or cloud integration

SBCs:

Native support for Ethernet, Wi-Fi, Bluetooth, and USB

Easily connect to cloud platforms (AWS, Azure, MQTT brokers)

Seamless integration with IIoT sensors and devices

✅ Advantage: SBCs excel in connected environments and Industry 4.0 applications.

Further Readings

→ The Official Raspberry Pi Beginners

→ Getting Started with Arduino: The Open Source Electronics Prototyping Platform

"To improve is to change, to be perfect is to change often"

3. Cost and Scalability

PLCs:

Cost can range from hundreds to thousands of dollars per unit

Expansion modules add to the price and footprint

Locked into vendor-specific ecosystems

SBCs:

Raspberry Pi starts under $100

Easily scalable with USB-based or GPIO-based I/O boards

Use open-source software and standard programming languages

✅ Advantage: SBCs enable rapid prototyping and low-cost deployment for small to mid-size automation systems.

Books For Yoga Beginners

4. Reliability and Industrial Readiness

PLCs:

Built for 24/7 uptime in harsh environments (temperature, vibration, dust)

Long support cycles and proven track record in mission-critical systems

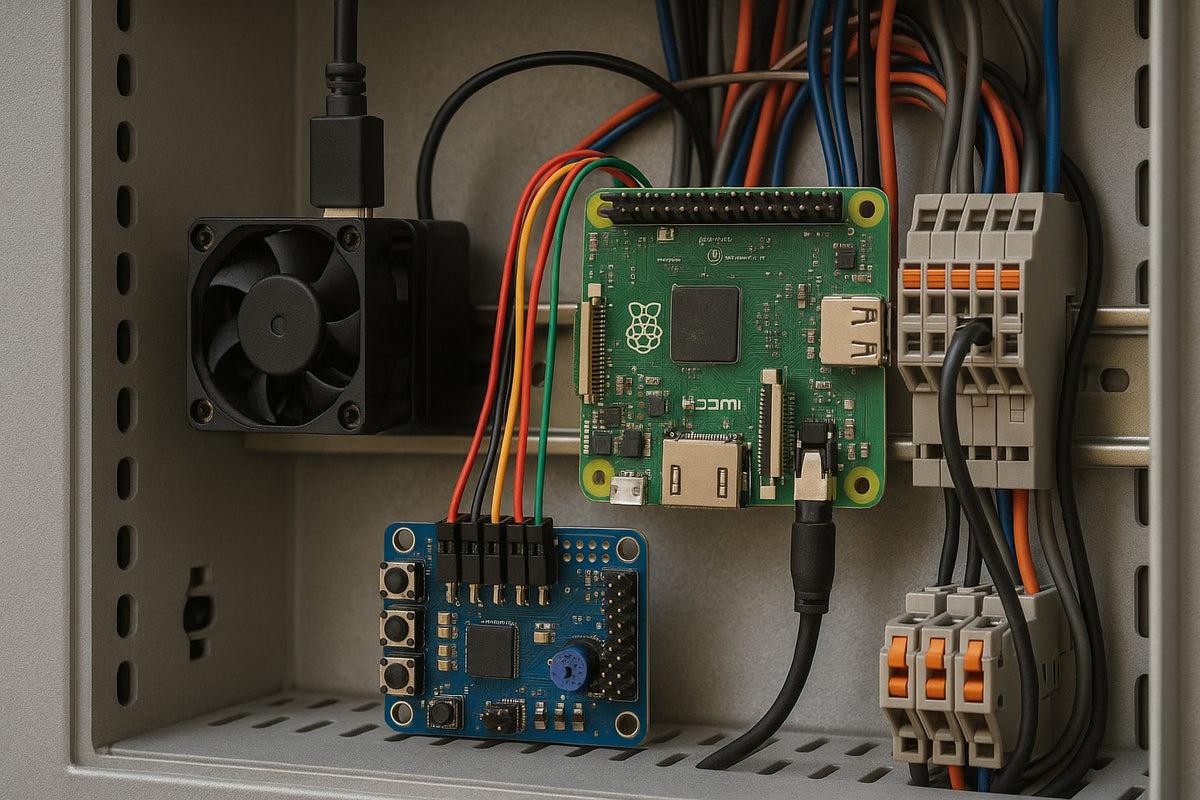

SBCs:

Not designed for industrial abuse out of the box

Require protective enclosures, industrial-grade power supplies, and watchdog timers

Reliability depends on software stability and environmental safeguards

✅ Advantage: PLCs remain unmatched in extreme industrial conditions, but SBCs can be hardened with proper engineering.

5. Use Cases in Industry

PLCs Are Best For:

Assembly line control

Safety-critical systems

High-reliability applications

SBCs Excel In:

Data acquisition and monitoring

Edge computing and IIoT gateways

Low-cost control for non-critical systems

Prototyping and retrofitting legacy systems

"I have not failed. I've just found 10,000 ways that won't work."

Further Readings

→ Programmable Logic Controllers

by Frank Petruzella

"When one door closes, another opens; but we so often look so long and so regretfully upon the closed door, that we do not see the ones which open for us".

Final Verdict: Complement, Not Replace—Yet

While Raspberry Pi and other SBCs won’t fully replace PLCs in the near future, they are becoming valuable complements in industrial environments. Their affordability, flexibility, and connectivity make them ideal for bridging the gap between legacy equipment and modern smart systems.

At EcoTech Solutions, we help businesses explore hybrid automation strategies—leveraging both traditional PLCs and cutting-edge SBCs to optimize performance and lower costs. If you're looking to modernize your plant with intelligent controls and industrial IoT integration, we’re ready to help you take the next step.

📞 Let’s Talk Automation

Whether you’re exploring edge computing, retrofitting legacy systems, or developing a custom SBC-based solution—EcoTech Solutions offers consultation, sourcing, and design support tailored to your industry needs.

#EcoTechSolutions #IndustrialAutomation #RaspberryPi #SmartFactory #PLCvSBC #EdgeComputing #IIoT #Industry40 #ControlSystems #AutomationEngineering

📞 Let’s Talk Automation

Products Featured In This Blog

Not entirely. While Raspberry Pi and other SBCs are excellent for data collection, edge computing, and low-risk automation, PLCs are still superior in high-reliability and safety-critical applications due to their ruggedness and deterministic control.

Raspberry Pi is being used in manufacturing , agriculture , energy , and facility management —mainly for monitoring systems, IIoT gateways, custom HMIs, and non-critical process control.

To harden a Raspberry Pi for industrial settings:

Use industrial enclosures and DIN rail mounts

Add a UPS or regulated power supply

Enable watchdog timers

Use industrial-grade SD cards or SSDs

Implement redundant software checks and remote monitoring

You can use Python, C++, Node-RED, or open-source PLC platforms like OpenPLC. Raspberry Pi also supports full operating systems like Linux, enabling integration with cloud services and APIs.

Lack of ruggedness for harsh environments

Susceptibility to power loss or SD card corruption

No native real-time, deterministic control without software tweaks

Shorter lifecycle support compared to PLCs

Yes! Many integrators use Raspberry Pi as a front-end system for data logging, HMI display, or IIoT gateway functionality, while retaining PLCs for core control. It's a great hybrid strategy.

Yes. Companies like OnLogic, Siemens (IOT2040), and others offer ruggedized single-board computers or Raspberry Pi-based platforms with extended temperature ratings, DIN rail mounts, and industrial certifications.

For non-critical applications, yes. SBCs can be cost-effective and scalable when used for monitoring, edge computing, or interfacing with legacy equipment. For core control systems, traditional PLCs remain more reliable at scale—at least for now.

EcoTech Solutions provides:

SBC hardware sourcing

Custom automation design support

IIoT and edge computing integration

Hybrid system consultation (SBC + PLC)

Prototyping, repair, and ongoing support